A circulating pump is a critical trouble in masses of heating structures. It is responsible for moving heated water via the system, ensuring an everyday heat flow inside a building. This pump is crucial in heating structures, allowing heat water to tour from the boiler to radiators, towel rails, and a one-of-a-kind home gadget. Without a central heating pump , your essential heating device ought not to be characteristically efficient, have maximum essentials for cold rooms, and have prolonged waits for decent water.

This article explains what a circulating pump is, how it works, its components, and any unusual issues that could arise.

What Is a Circulating Pump?

A circulating or circulator pump is a water booster pump designed to move heat water via a heating device. The pump flows hot water from the boiler via a network of pipes into appliances like radiators or heat water cylinders. Once the water cools, it returns to the boiler to be reheated and despatched via the device.

Where Are Circulating Pumps Used?

Circulating pumps are most typically located in critical heating structures in houses and workplaces. They also are applied in hydronic heating systems, which rely on water to change warm temperatures during construction. These pumps help circulate water through warmth exchangers, like radiators, to ensure even heating in every part of the building.

A water circulation pump may supply warm water to extraordinary areas in big homes or houses with more than one heating zone.

How Does a Circulating Pump Work?

A circulating pump brings water into the pump through a bay, moves it through it utilizing an impeller, and pushes it out through an outlet. The pump utilizes outward strain to keep the water moving. The impeller inside the pump rotates, causing the water to move fast and with immoderate pressure.

Here's a clean breakdown of techniques it in truth works:

Water enters the pump through the inlet.

The impeller spins, growing centrifugal strain, which pushes the water beforehand.

Water is pressured from the pump into the pipes, traveling through radiators, warm water chambers, or other home gear.

Yet again, after the water cools, it returns to the kettle to be warmed, and the cycle starts offevolved.

The pump's speed can be regularly adjusted to match the gadget's dreams. A faster pump speed runs water extra fast, delivering quicker warmth to at least one-of-a-kind gadget components.

Key Components of a Circulating Pump

A hydronic system pump consists of several critical additives. Understanding these factors can help you troubleshoot any issues that might arise.

Pump: This is the principal body of the pump that moves the water through the gadget.

Motor: The motor powers the pump, converting electric power into mechanical strength. This power turns the impeller, which actions the water.

Impeller: A minor fan-like issue in the pump that spins and creates the centrifugal pressure needed to skip the water.

Inlet and outlet: These are the pump's access and exit points. Water enters through the inlet and is pushed out through the hollow.

Rotor and shaft: The rotor is installed on the impeller and turns along its side, shifting water through the gadget. The shaft holds the entirety in place and allows for easy operation.

Volute: The casing throughout the impeller collects the water because it exits and directs it out of the pump.

Common Circulating Pump Problems

While hot water booster pumps are reliable, problems can arise over the years. Here are some not-unusual troubles and what to do about them:

Noisy Pump

A noisy pump is usually a sign of an airlock. This co-occurs as the air gets trapped in the pump, stopping the water from flowing correctly. You can recover this by bleeding the pump. Turn off the strength supply, and use a screwdriver to loosen the bleed screw. This will allow the trapped air to break out. A free bearing or a few other mechanical hassles may need professional interest if the noise persists.

Leaking Pump

Leaks are a common problem due to a worn-out seal or loose fittings. To heal this, check all the joints and tighten them with a spanner. If you discover a corroded element or a blown seal, you could need to replace it. The The whole pump should likely be replaced a few times if it's too vintage or broken.

Radiators Not Heating Up

However, if your radiators are cold and the pump is stuttering, the framework may have blockage. A buildup of slop or particles can stop the pump and keep water from flowing. You may need a professional to perform a device flush or smooth the pump to remedy this hassle.

FAQs about Circulating Pumps

How frequently should a circulating pump be replaced?

A boiler circulation pump can last up to 10 years or more with proper protection. However, if it regularly breaks down, it might be time to update it.

Why is my circulating pump making a buzzing noise?

A humming noise can be caused by an electrical problem or a motor malfunction. It's superb to have a professional examine the pump to determine the reason.

Can I alter the speed of my circulating pump?

Yes, many Inline centrifugal pumps have adjustable velocity settings. Changing the fee can assist in decorating water glides and heating efficiency on your gadget.

In Wrap Up

A circulating pump is a vital part of your heating device. It ensures warm water flows continuously through your house, providing warmth and comfort. Knowing how aheating system circulatorworks and being aware of unusual troubles can help you maintain your heating device without problems. Regular protection and troubleshooting can help prevent more severe troubles, save time and money.

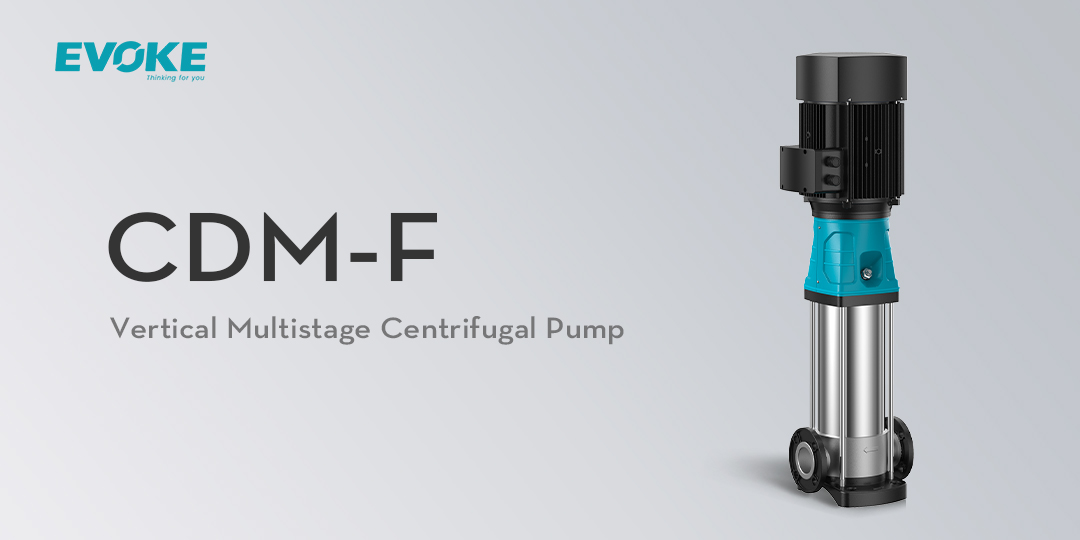

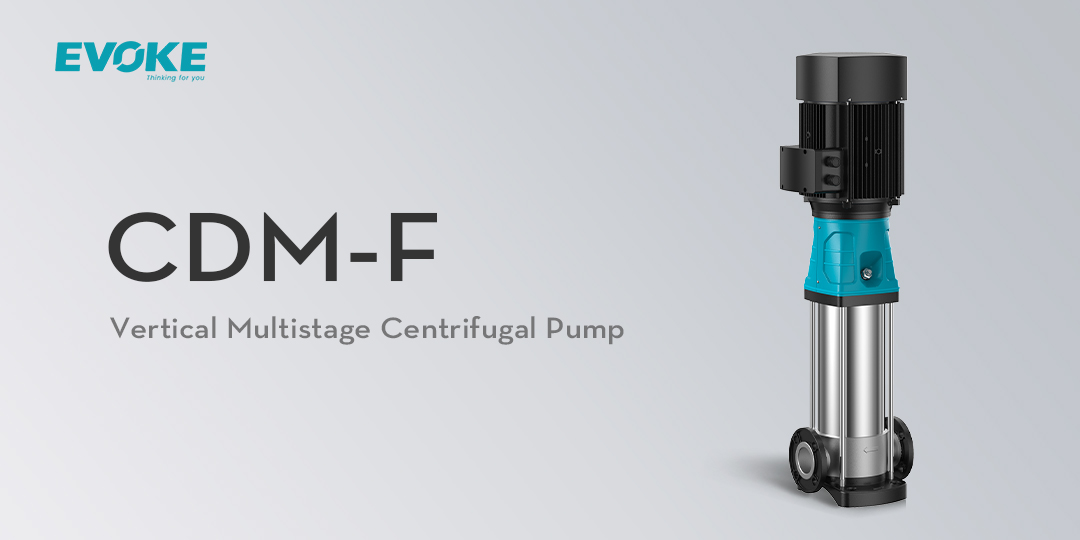

If you're experiencing continual troubles with your circulating pump, EVOKE offers customers better company, innovation, and charge. We are one of the world's fundamental tremendous providers.